Water management equipment

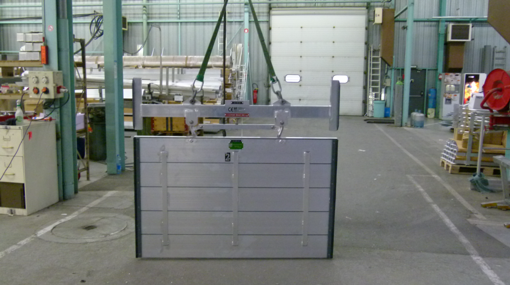

Stop log and accessories

Watertightness:

- Maximum leak rate according to DIN 19569-4 class 1 (0.3 to 1.0 l/linear meter/sec.)

- Sealing on three (3) or four (4) sides

- Possibility of reducing the leakage rate to approximately 2 litres/hour/m2 or less: on demand !us

Materials :

- Aluminum extruded alloy profiles (Al Mg Si 0.7)

- Stainless steel folded plate (Grade AISI 304L or 316 TI)

- GRP-Composite

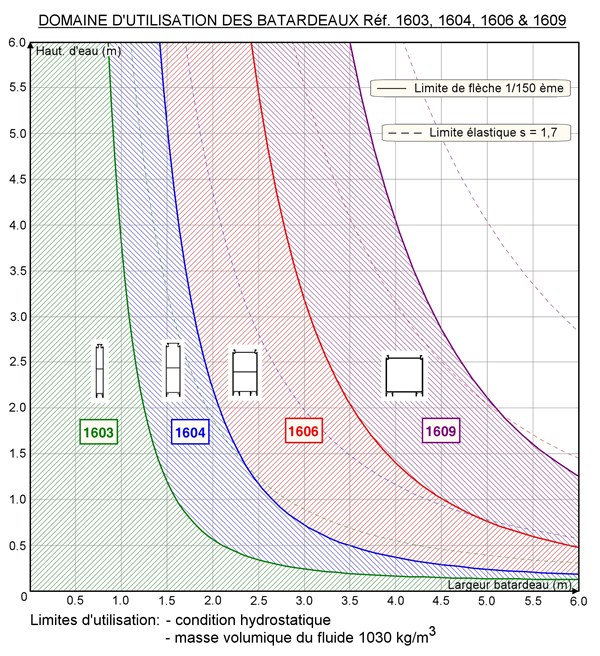

Design and standard service stress:

- Max. 1/150th deflection limit

- The elastic limit plus safety factor of 1,7

- For a fluid density of 1030 kg/m³

Aluminum stop log:

- Made up of stacked profiles.

- Choice of profile according to the operating loads :Profile ref. 1603 (30mm width) ref. 1604 (60mm width) ref. 1606 (100mm width) and last, ref. 1609 (width 150mm). Profile heights: 105, 185 and 205 mm.

In the event of a water load exceeding the limits of the profile utilization diagram, it is possible to reinforce the logs which will be designed after a stress calculation by our R&D engineer.

The stop log can be made up of one (1) or more elements, depending on whether it is for manual handling (maximum lifting effort of 100 daN) or mechanical handling by beam (maximum lifting force of 500 daN)

Aluminum frame:

U-shaped aluminum profile with fixing grooves for our seals. The seals are easily replaceable.

Dimensions in relation to the chosen log model (art. nr. 1603, 1604, 1606 or 1609) The frame consists of 3 parts, assembled by welding or bolted (for oversize length). The frame can be embedded in a concrete rabbet or screwed, either between walls (type C) or against wall (type D) Water pressure, by default, is always understood as compression. 316TI stainless steel hardware is provided for bolt-on frame attachment.

Steel stop log and frame:

- Any size available, made in smooth folded sheet metal, sheet thickness according to load with stiffeners according to static calculation.

- U shaped sheet in maximum length of 3000 mm (for longer one size piece, on demand) beyond assembly by bolts and fishplates.

The frame consists of 3 parts, assembled by welding or bolted. The frame can be embedded in a concrete rabbet or screwed, either between walls (type C) or against wall (type D) Water pressure, by default, is always understood as compression. 316TI stainless steel hardware is provided for “bolt-on” option frame attachment

Assembly characteristics :

- TIG-MIG welding assembly for Aluminum or steel

- Glued for GRP stop-log

- EPDM seals, easily interchangeable as they are inserted into ad-hoc grooves in the frame profile (aluminium version) or fixed by screwing onto the folded sheet metal cofferdam boards (steel version frame)

Scope of use of stop logs

Accessories for stop log

STOP LOGS

ACCESSORIES FOR STOP LOGS

All tailor-made solutions available